Sensors are playing a major role in industry 4.0 which is leading to major growth in the global sensor market. The shift to in-process use of long range sensors for condition monitoring plays a huge part in industrial control strategy is just one example. This points to their role in automation across automotive, aerospace, and manufacturing industries for process control.

Industry 4.0 market applications of long range distance sensors encompass everything from factory automation and robotics, agile production lines, and smart manufacturing to retail inventory control and supply chain. Automation is a key component to the push for self- optimization in manufacturing processes. Sensors are at the heart of these automated manufacturing systems. As part of that broader system, they enable everything from assembly line and conveyor production processes to robotic collision avoidance and human machine interactions.

Process control is everything in many industries where close variable monitoring of fluid levels, pressure sensitivity, temperature range, and flow among others are the foundation of production cycles. The rise of Internet of Things (IoT) and specifically industrial internet of things (IIoT) are fueling the process control and monitoring aspects of industry 4.0.

There are countless sensors vital to the continual monitoring process and industrial process control where long range sensors play an important role. There are also dozens of different sensors deployed across IoT-enabled industries that play a huge part in industrial control because of their ability to provide remote sensing actions and monitoring capabilities.

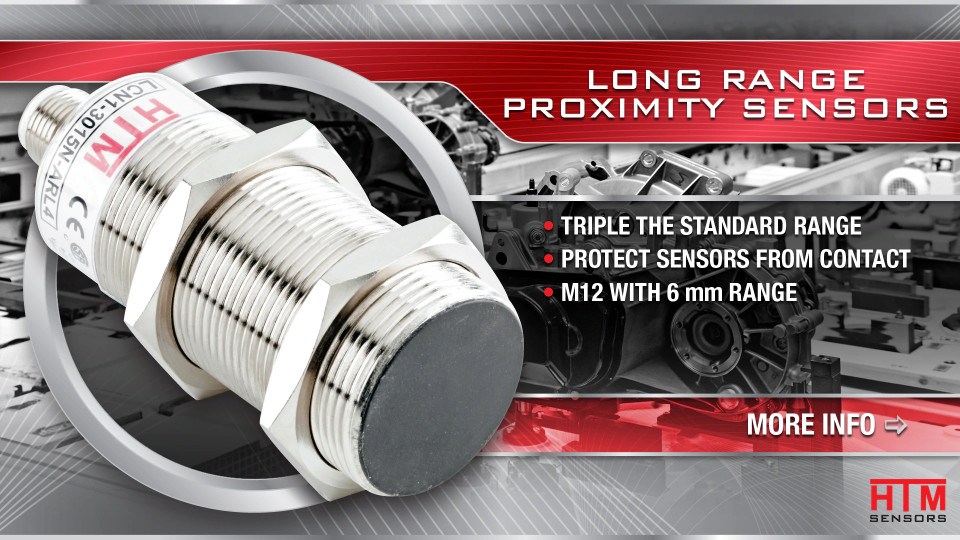

Modern production lines across nearly every industry sector are reliant on sensors as part of customized automation production solutions to monitor material flow. Traditional conveyer manufacturers have made long range distance sensors a part of their systems to expand production automation possibilities without introducing process interference due to proximity.

Everyone from small shops to global manufacturing operations are looking for innovative and practical ways to enhance productivity and accuracy. These goals share equal weight with the need to lower waste and process delays using the long range proximity sensor. Several key market analysis surveys show that sensors are expected to generate revenue of $4,101.1 million by 2021 in industrial control applications.

In fact, sensors will see significant growth opportunities as a means for leveraging IIoT for advanced automation of processes in the manufacturing environment. The major arenas for Industry 4.0 market applications imply a significant growth potential for the sensors market.

Long range distance sensors are crucial for downtime avoidance in manufacturing where distance is a big part of reducing environmental resistance and process interference. Working in conjunction with IO-Link functionality, these sensors can indicate the points of potential process slowdowns and failures. Long sensing distance essentially prevents unexpected equipment downtime caused by target contact.

Sensors are increasingly being deployed for process control, automated production lines, and more by leveraging connectivity, IoT process control, data sharing, and logistics integration. As industry 4.0 continues to transform manufacturing operations across small and large environments, the long range proximity sensor in different forms and types will play an increasingly important role.

Canadian Dollars

Canadian Dollars

USD

USD